Conversion costs play a crucial role in the manufacturing sector, as they represent the expenses incurred in transforming raw materials into finished products. By examining the formula for calculating these costs, businesses can gain insights into their production efficiency. Practical examples illustrate the impact of understanding conversion costs on profitability. This analysis raises important questions about how these costs influence overall competitiveness and operational strategies in a dynamic marketplace.

Understanding Conversion Costs

Conversion costs are a critical component of manufacturing expenses, encompassing the total costs incurred to convert raw materials into finished goods.

Understanding these costs is essential for evaluating manufacturing efficiency. They typically include direct labor and manufacturing overhead, influencing overall production effectiveness.

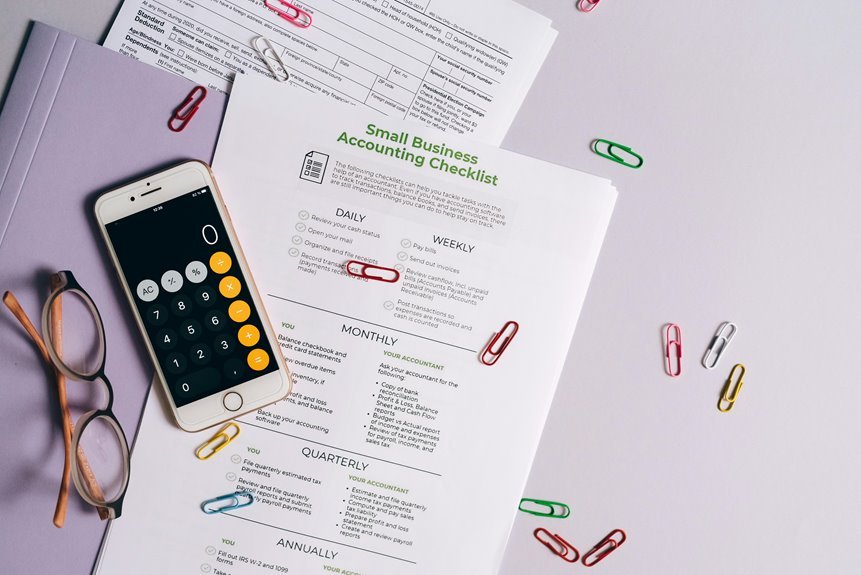

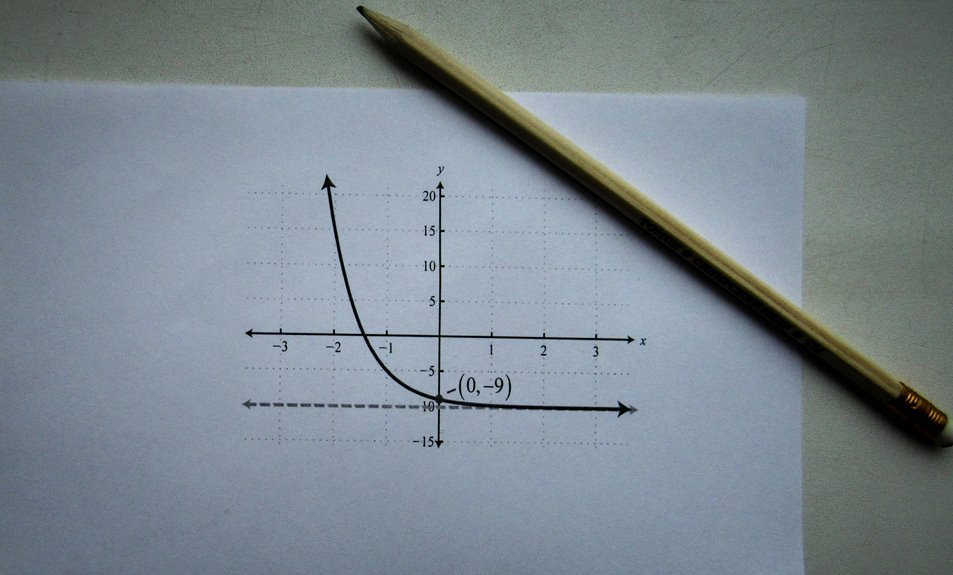

Calculating Conversion Costs: The Formula

The calculation of conversion costs involves a straightforward yet essential formula that aids in accurately assessing manufacturing expenses.

This formula combines direct labor costs and manufacturing overhead. Specifically, conversion costs are calculated by adding total direct labor expenses to total manufacturing overhead costs incurred during a specific period.

This approach provides manufacturers a clear view of the costs associated with transforming raw materials into finished products.

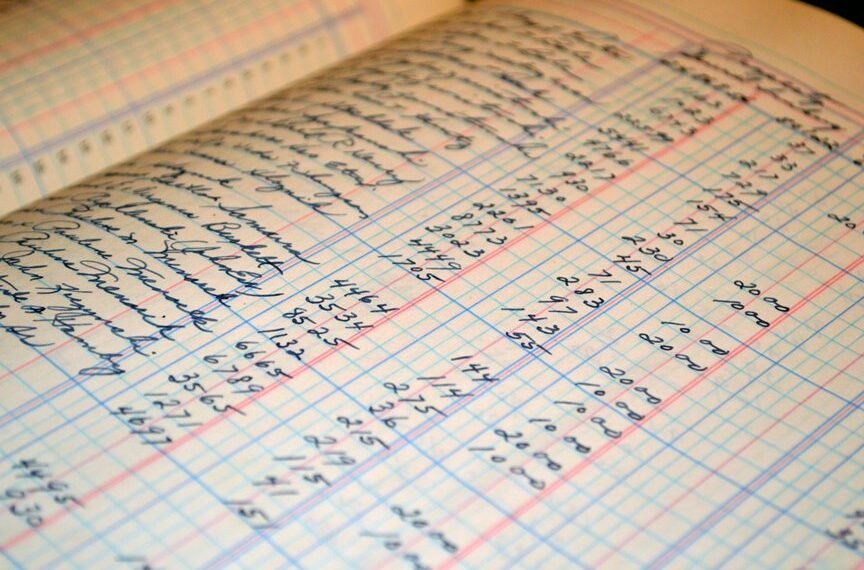

Practical Examples of Conversion Costs

While examining practical examples of conversion costs, one can discern how these expenses manifest in various manufacturing scenarios.

Consider a furniture manufacturer assessing labor efficiency alongside overhead allocation. By tracking direct labor hours and indirect costs, the company can identify inefficiencies, optimize production processes, and enhance profitability.

Such analysis highlights the integral role conversion costs play in efficient manufacturing operations.

Importance of Conversion Costs in Manufacturing

Understanding the importance of conversion costs in manufacturing is crucial for companies aiming to enhance operational efficiency and profitability.

By analyzing conversion costs, firms can identify areas to improve cost efficiency within their manufacturing processes. This insight enables better resource allocation, reduces waste, and ultimately leads to increased competitiveness.

A keen focus on conversion costs fosters sustainable growth in a dynamic market environment.

Conclusion

In conclusion, conversion costs serve as a critical metric for manufacturers seeking to optimize their production processes. While some may argue that focusing solely on these costs overlooks the significance of raw material expenses, a comprehensive understanding of conversion costs allows for a holistic view of operational efficiency. By analyzing these costs in conjunction with raw material expenditures, manufacturers can unlock significant insights that drive profitability and enhance competitive positioning in the marketplace.