Direct materials serve as the backbone of manufacturing, directly linked to the creation of final products. Understanding their significance is crucial for industries ranging from automotive to electronics. Each sector relies on specific materials to enhance quality and reduce costs. How do these components impact overall competitiveness? Exploring practical examples reveals a deeper insight into their effective management and the benefits that follow. The journey into this essential aspect of production is just beginning.

Definition of Direct Materials

Direct materials serve as the essential building blocks of a product, embodying the raw components that are directly traceable to the final output.

In the realm of cost analysis, understanding these materials is vital, as they significantly impact production expenses.

Importance of Direct Materials in Manufacturing

The role of direct materials in manufacturing cannot be overstated, as they form the core of production processes and significantly influence the overall quality and cost-effectiveness of products.

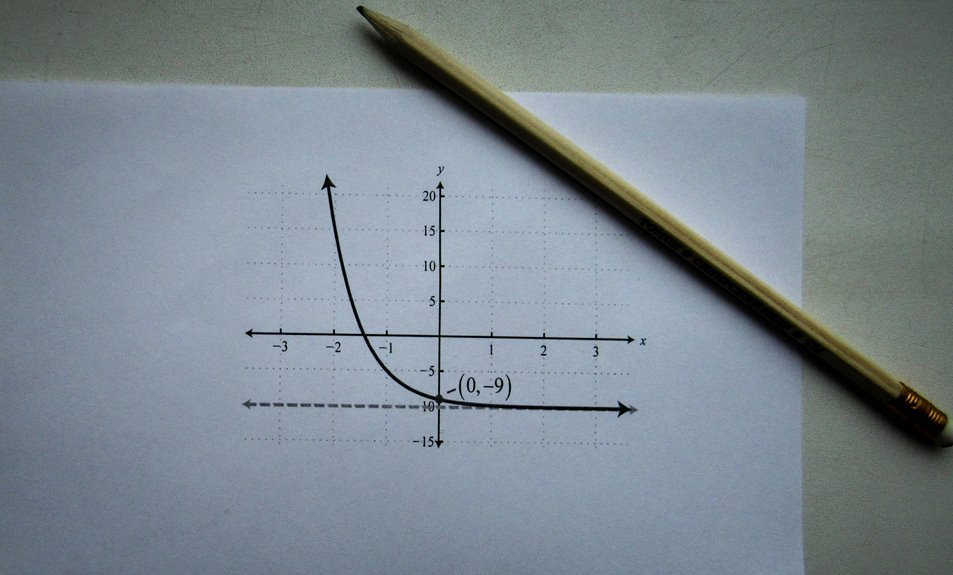

Effective cost analysis of direct materials is essential for optimizing budgets, fostering better decision-making.

Additionally, their management within the supply chain ensures timely availability, ultimately enhancing productivity and maintaining competitiveness in a dynamic market landscape.

Examples of Direct Materials in Various Industries

In the intricate tapestry of various industries, direct materials serve as the essential threads that weave together the final product.

In automotive manufacturing, steel and plastic form crucial automotive components, enabling vehicles to function seamlessly.

Meanwhile, the textile industry relies on vibrant textile fibers, transforming them into clothing and upholstery.

Each industry highlights the diverse applications of direct materials in crafting unique products.

Strategies for Managing Direct Materials Effectively

Effectively managing direct materials can significantly enhance operational efficiency and reduce costs within an organization.

Key strategies include implementing robust inventory control systems to monitor stock levels and reduce waste. Additionally, fostering strong supplier relationships ensures timely delivery and quality materials.

Conclusion

In conclusion, direct materials are the backbone of manufacturing, influencing product quality and cost efficiency. For instance, a hypothetical automotive company that optimizes its steel sourcing can significantly reduce production costs and improve vehicle durability. By strategically managing these essential components, businesses not only enhance their competitive edge but also foster innovation. Ultimately, the effective handling of direct materials paves the way for success in an ever-evolving market landscape, underscoring their critical role in manufacturing excellence.